Keep your process in sync

Assure

Avoiding delays in your gob delivery is vital for your process' reliability. The right delivery equipment lubricant controls the friction between glass and metal and assures on-time delivery.

Prevent

Keeping your delivery equipment clean is essential for preventing container contamination. Our delivery equipment lubricants help you reduce the risk of contamination.

Extend

Your maintenance team should have time for preventive and predictable maintenance tasks. Interglass' delivery equipment lubrication helps you recover valuable maintenance time.

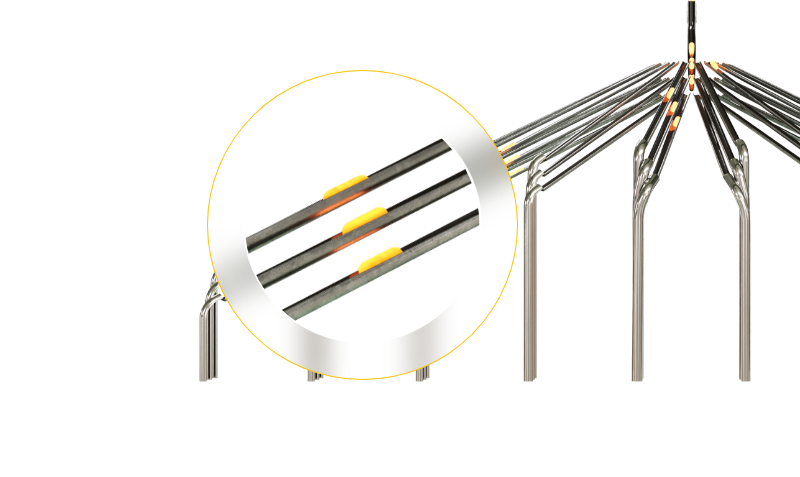

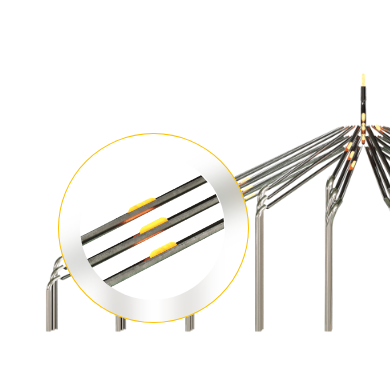

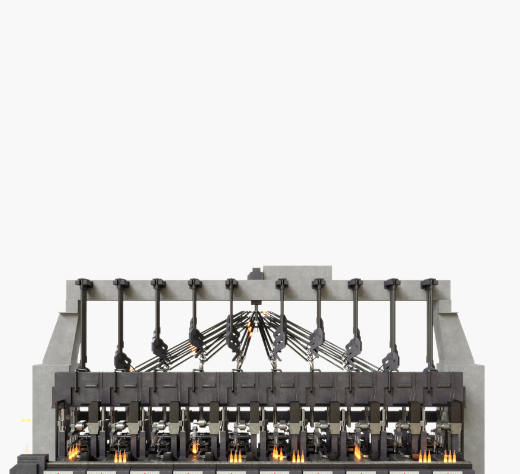

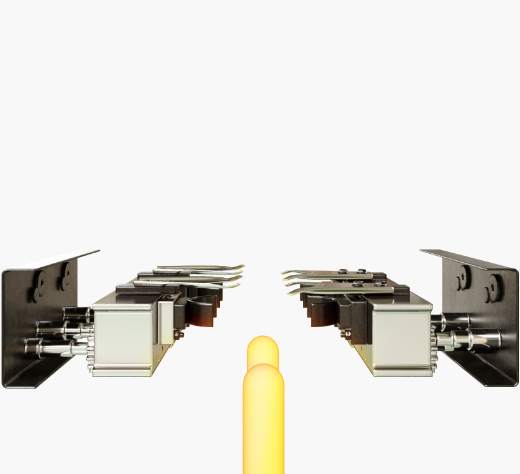

EPOXY COATINGS FOR TROUGHS AND DEFLECTORS

Maintain clean and constant delivery cycles.

Your delivery equipment keeps your IS machine synchronized. When gobs arrive on time and without contaminants in blank molds, you guarantee your process’ reliability.

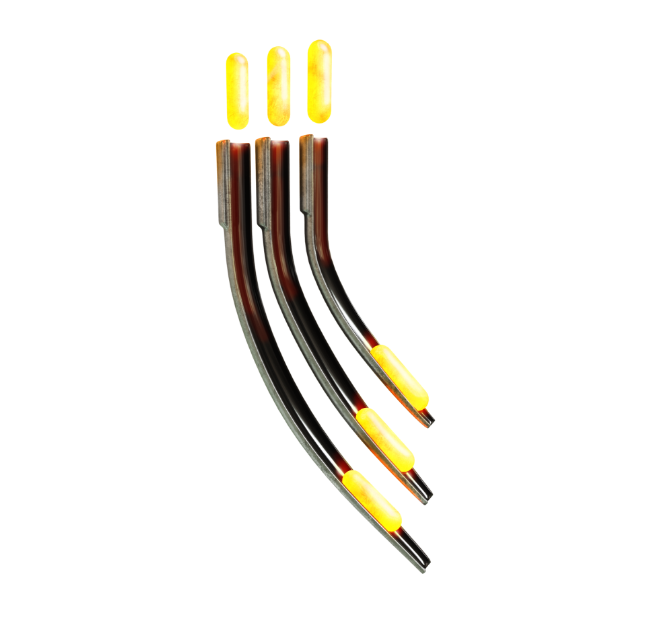

Slide Film

Dry delivery coating for grooved finishes

For minimizing contact between glass gobs and troughs/deflectors. It keeps delivery speeds constant.

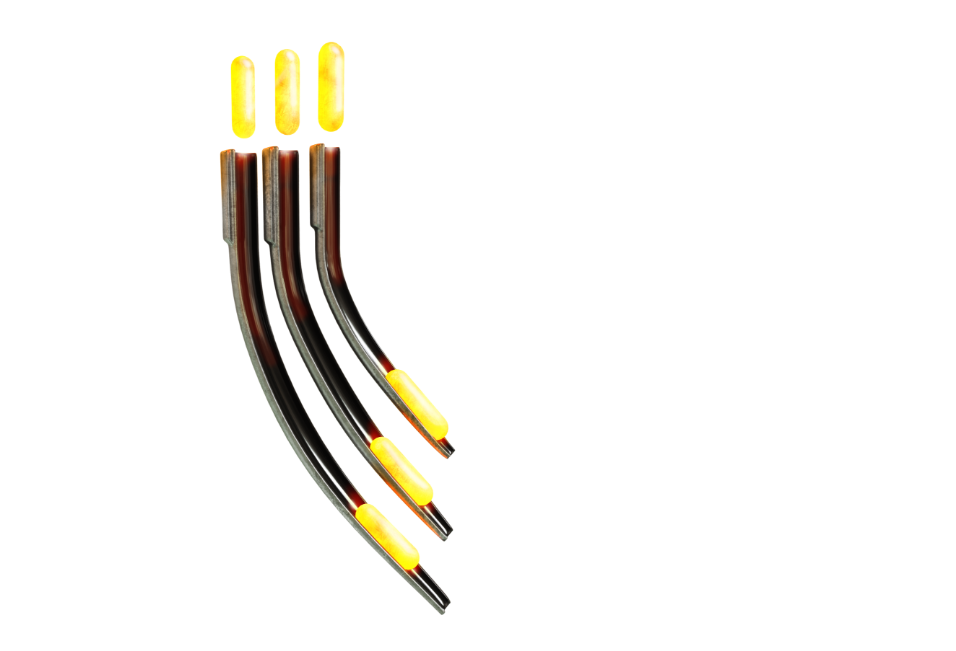

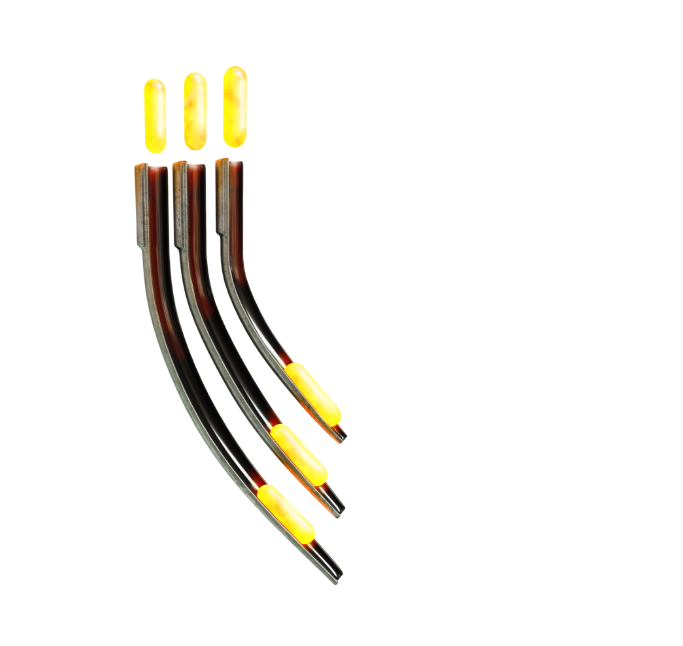

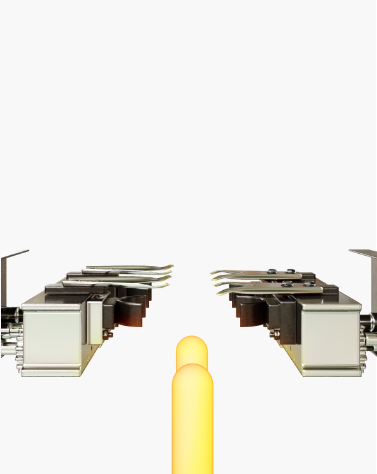

Learn moreSCOOP OILS

Control contamination and reduce scrap.

Whatever your requirements are, our team has developed synthetic, semisynthetic, and mineral-based scoop oils with different viscosity levels.

Slide Oil 68 P

Semisynthetic scoop oil

For high-speed operation and reducing scrap generated by contamination. It contains special additives to withstand evaporation and oxidation.

Learn more

By identifying and implementing ideal delivery equipment lubrication solutions for leading glassmakers around the world, we’ve helped them keep their quality indicators healthy—and thriving.

Let us help you make glass better

Discover your improvement potential

We analyze the key variables that tend to limit your process’ efficiency and productivity.

Receive personalized recommendations

Then, we design a swabbing strategy that improves your quality metrics and increases the reliability of your process.

Validate the strategy in one of your lines

Finally, we help you implement the strategy in select lines, document performance metrics, and validate its effectiveness.