Increase the reliability of your distribution system

Care

Want to reduce your ecological impact and take your plant to the next level? We’ll make your transition to bio-synthetic lubricants easy and rewarding.

Resilience

Interglass' new generation of vegetable-based lubricants help avoid bacteria attacks and maintain stable emulsions, even in variable water conditions.

Flow

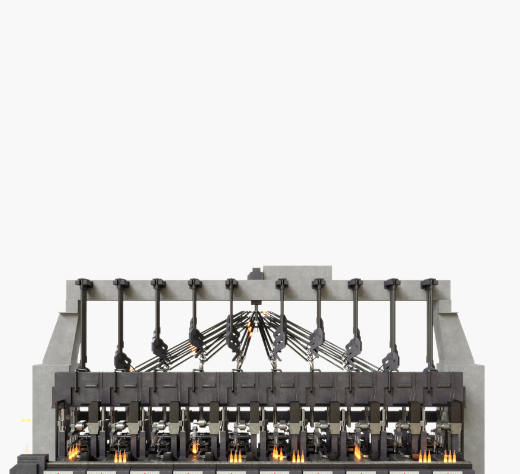

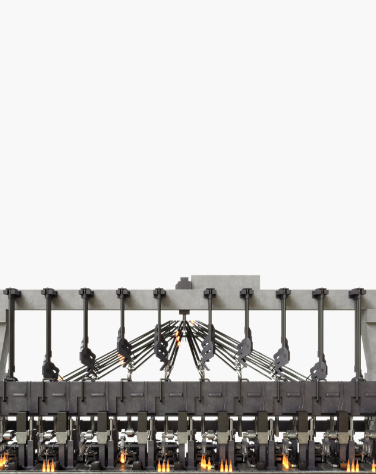

Your blade cutting system sets your plant’s rhythm. Its optimal performance guarantees a constant feed to your glass-forming process.

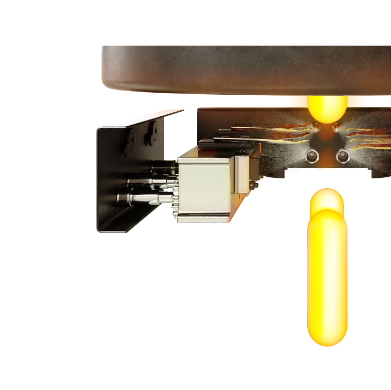

SHEAR BLADE COOLING LUBRICANTS

Protect your blades, your process, and the environment.

The optimal performance of your shear blades determines the efficiency of your overall process. Selecting the ideal lubricant not only assures the resilience of your blades, but also of your complete spraying system.

B-Lub

Biodegradable, vegetable-based oil

For maximum lubricity and efficient cooling of shear blades in variable water conditions.

Learn more

Cut Bio 1000

Biodegradable, synthetic-based oil

For shear blade lubrication. Contains bactericides, corrosion inhibiters, and moisturizers.

Learn more

By identifying and implementing ideal shear blade lubrication solutions for leading glassmakers around the world, we’ve helped them keep their quality indicators healthy—and thriving.

Let us help you make glass better

Discover your improvement potential

We analyze the key variables that tend to limit your process’ efficiency and productivity.

Receive personalized recommendations

Then, we design a swabbing strategy that improves your quality metrics and increases the reliability of your process.

Validate the strategy in one of your lines

Finally, we help you implement the strategy in select lines, document performance metrics, and validate its effectiveness.