Identify

One size does NOT fit all. Our highly specialized swabbing compounds will help you reduce defects, even in neck rings and in more elaborate bottles.

Implement

Getting a new product line up and running inevitably produces waste. We’ll identify and recommend the ideal Glassmold solution for your projects.

Improve

The pressure is on you to increase profit margins. The right swabbing compounds will help you improve your pack-to-melt ratio and lubricant consumption.

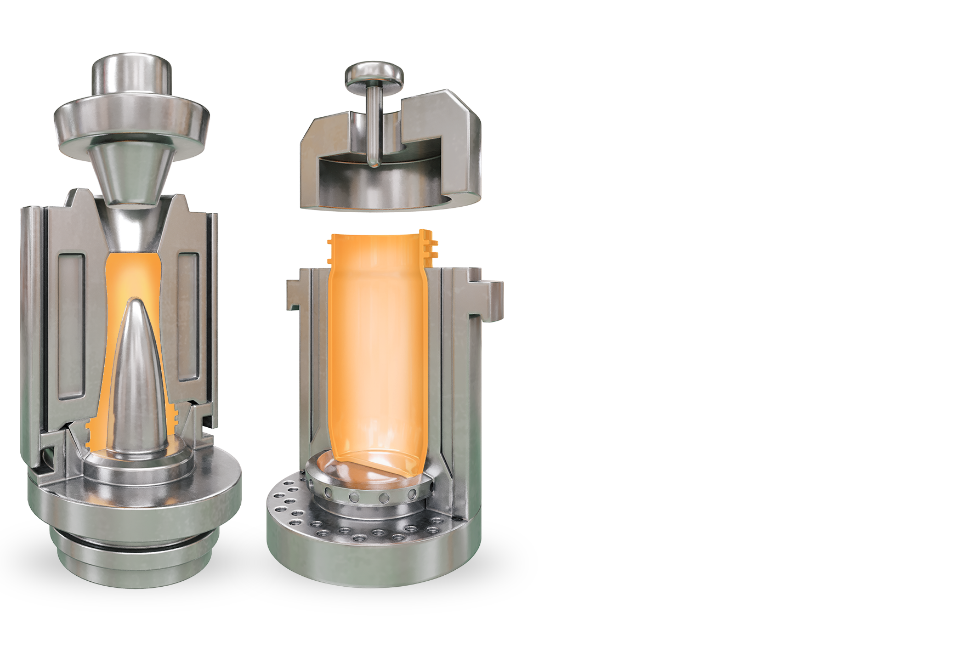

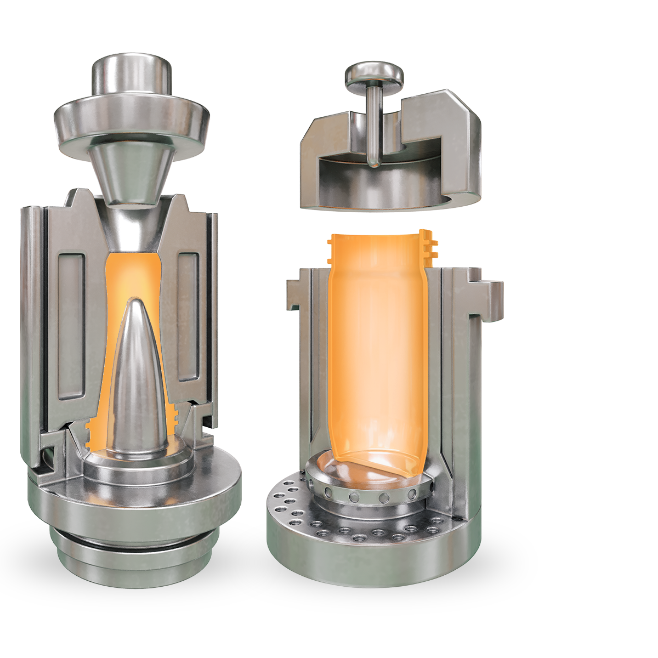

SWABBING COMPOUNDS FOR

BEER AND SODA CONTAINERS

Improve your pack-to-melt ratio

NNPB swabbing compound for high speeds

For improving beer and soda container processing efficiency and extending lubrication cycles.

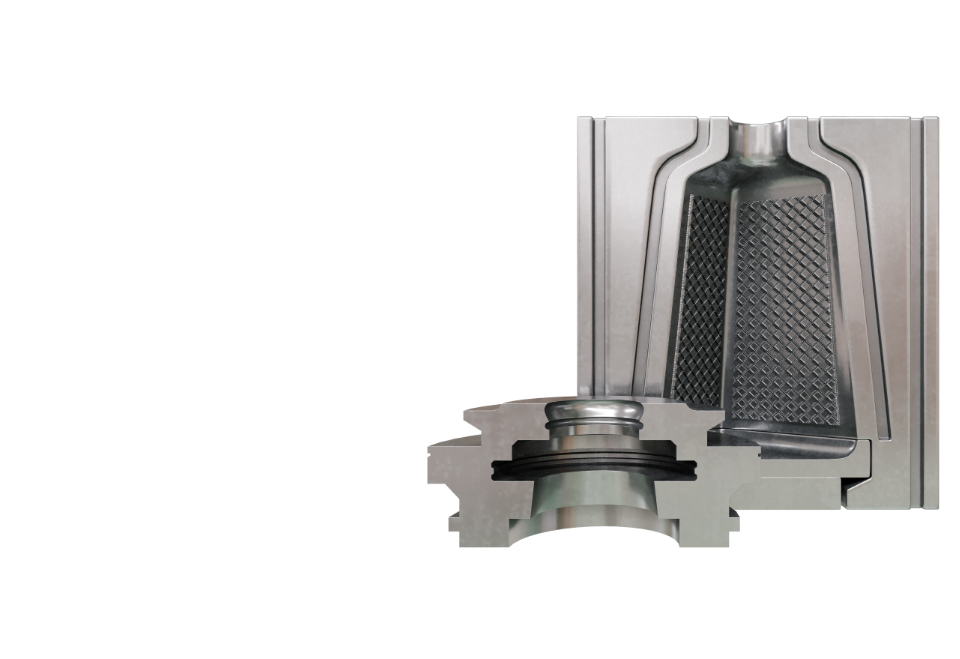

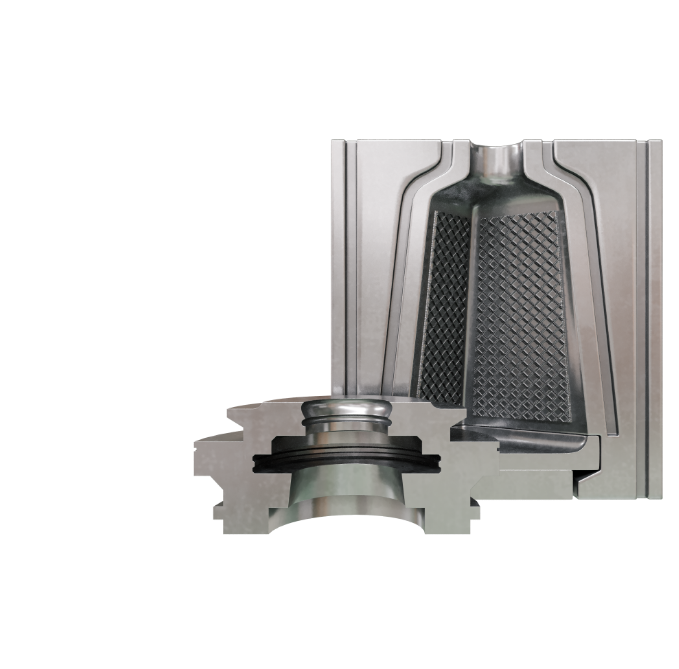

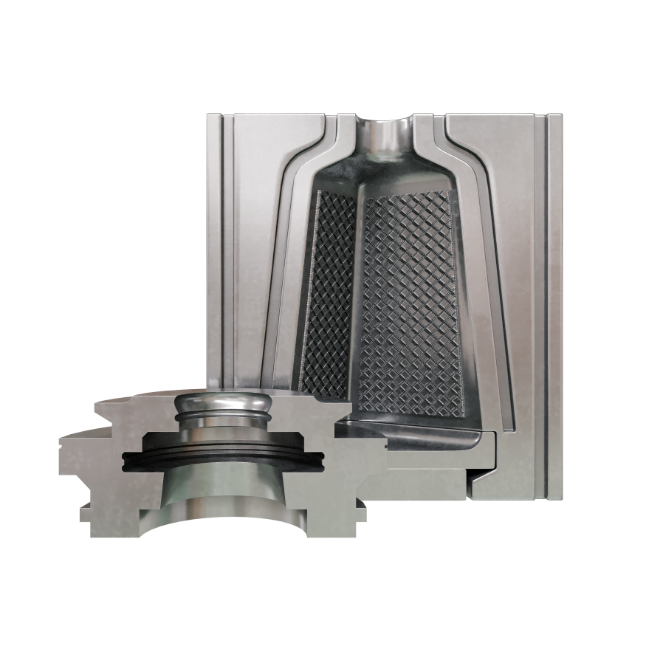

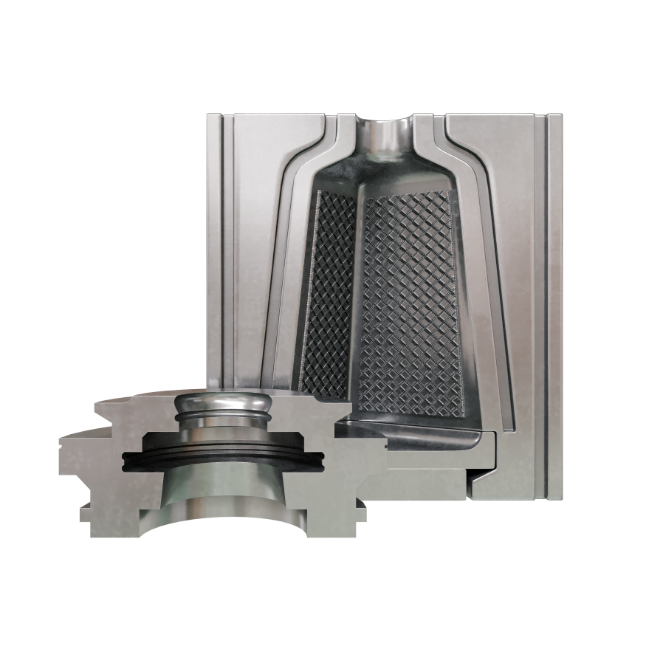

Learn moreSWABBING COMPOUNDS FOR WINE

AND SPIRIT CONTAINERS

Reduce scrap and improve appearance.

Long lasting, blow-blow swabbing compound

For reducing wine and spirit container defects and/or impurities and extending lubrication cycles.

Learn moreSWABBING COMPOUNDS FOR FOOD AND

PERFUME CONTAINERS

Reduce annoying defects and impurities.

General use, blow-blow swabbing compound

For reducing food and perfume container defects and/or impurities.

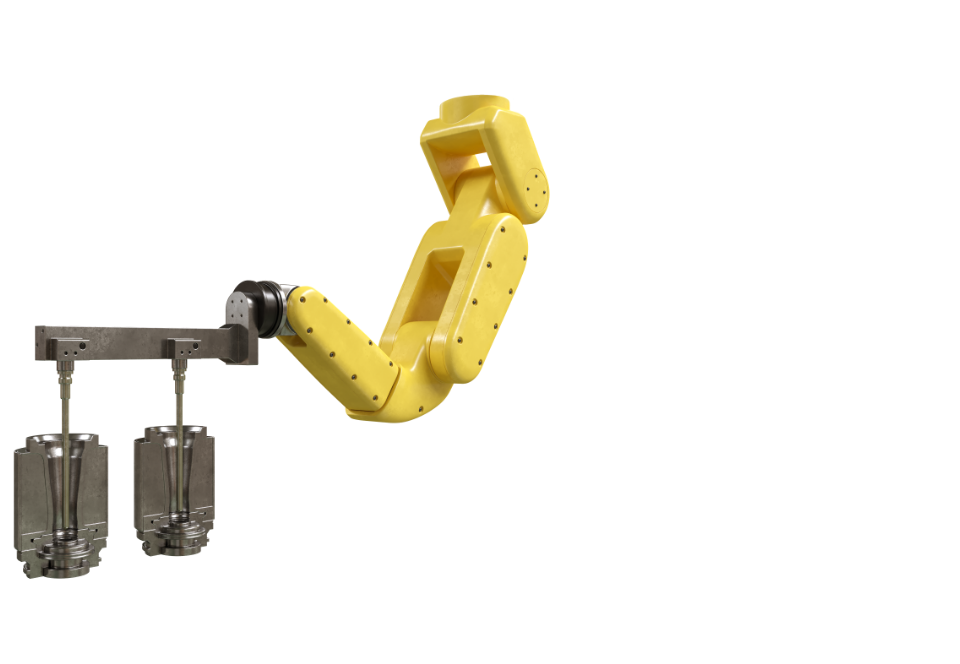

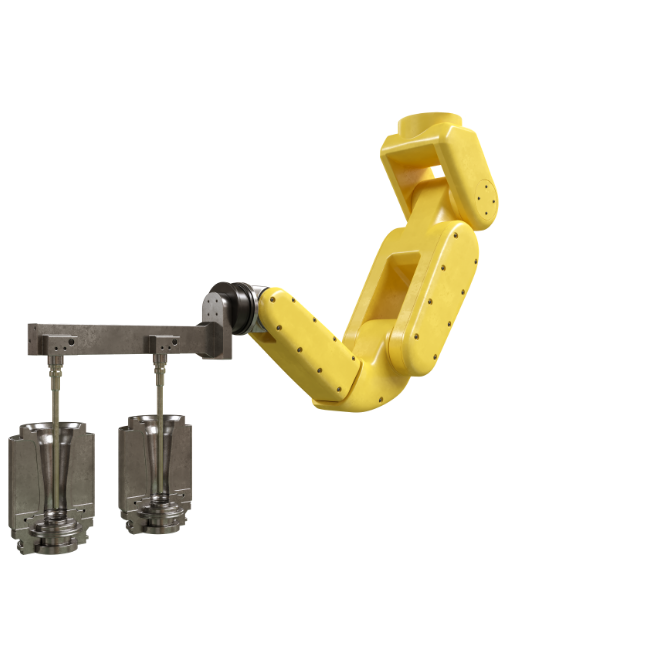

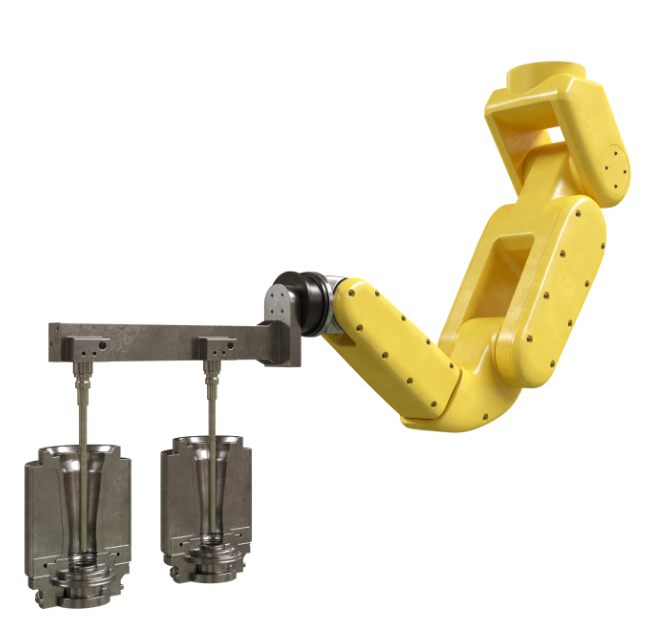

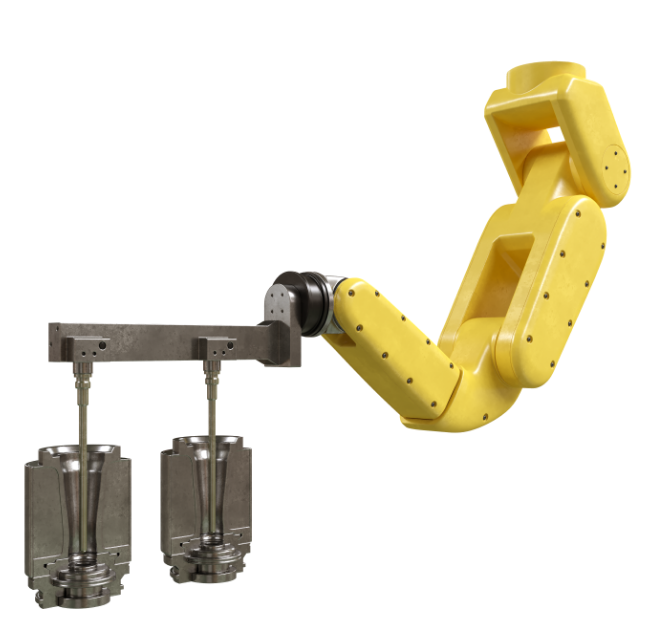

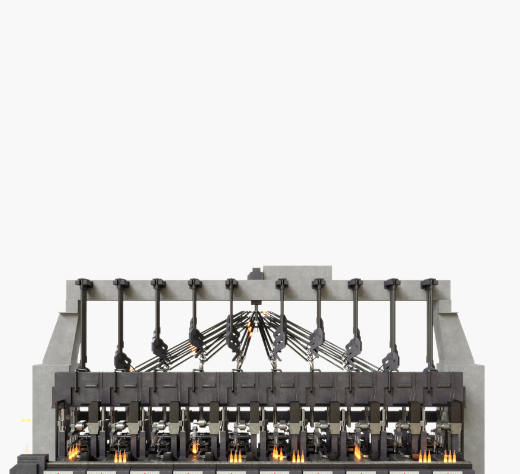

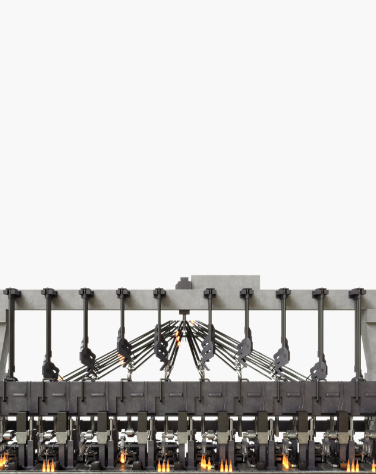

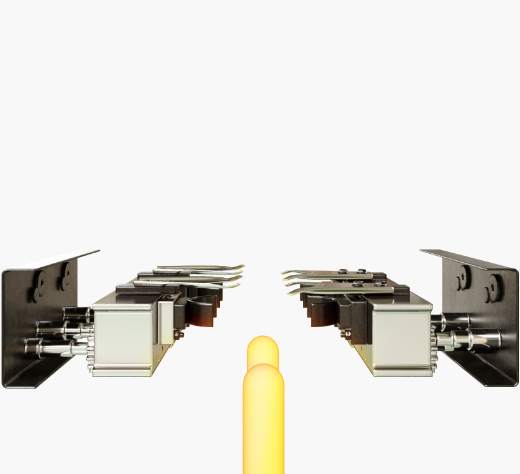

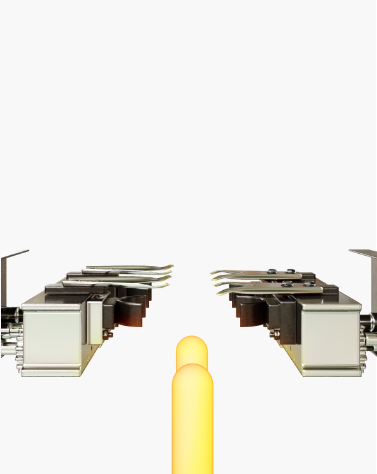

Learn moreAUTOMATED SWABBING SYSTEMS

Tap into the potential of new, cutting-edge technologies.

Clog-free swabbing compound for robotic systems

For maintaining stable glassmaking operations. Its viscosity is specific to each application.

Learn more

SWABBING COMPOUNDS FOR SPECIAL APPLICATIONS

The devil is in the details.

Small container design elements produce huge challenges. Discover specialized touch-up and neck ring swabbing compounds to optimize container appearance.

Super low viscosity touch-up lubricant for glassware

Designed for glassware processes where solid lubricant dispersion is key.

Learn more

Low viscosity swabbing compound for neck rings

For quick, on-the-fly lubrication.

Learn more

Low viscosity touch-up lubricant

For on-the-fly lubrication of larger container surfaces.

Learn more

High viscosity touch-up lubricant

For careful, specific lubrication of logos, registers, and other container engravements.

Learn more

By identifying and implementing ideal Glassmold solutions for leading glassmakers around the world, we’ve helped them keep their quality indicators healthy—and thriving.

Let us help you make glass better

Discover your improvement potential

We analyze the key variables that tend to limit your process’ efficiency and productivity.

Receive personalized recommendations

Then, we design a swabbing strategy that improves your quality metrics and increases the reliability of your process.

Validate the strategy in one of your lines

Finally, we help you implement the strategy in select lines, document performance metrics, and validate its effectiveness.